Cities are turning to vertical farms to keep their supply chains upright

As urban grocery stores struggle to stock enough produce for their customers, they’re finding a seedling of hope.

Published:

Updated:

Related Articles

-

-

Lab-grown meat to save the eels — and your sushi

-

Why, though? A beverage you can chew

-

The $5m lawsuit over a missing jack-o’-lantern face

-

Hungover? Burger King’s facial recognition tech has a deal for you

-

Chipotle’s love of robots continues with autonomous farming

-

A latte to think about: Coffee is coming home in 2024

-

Food brands are cooking up new offerings to pair with weight loss drugs

-

A sci-fi McDonald’s appears in Illinois

-

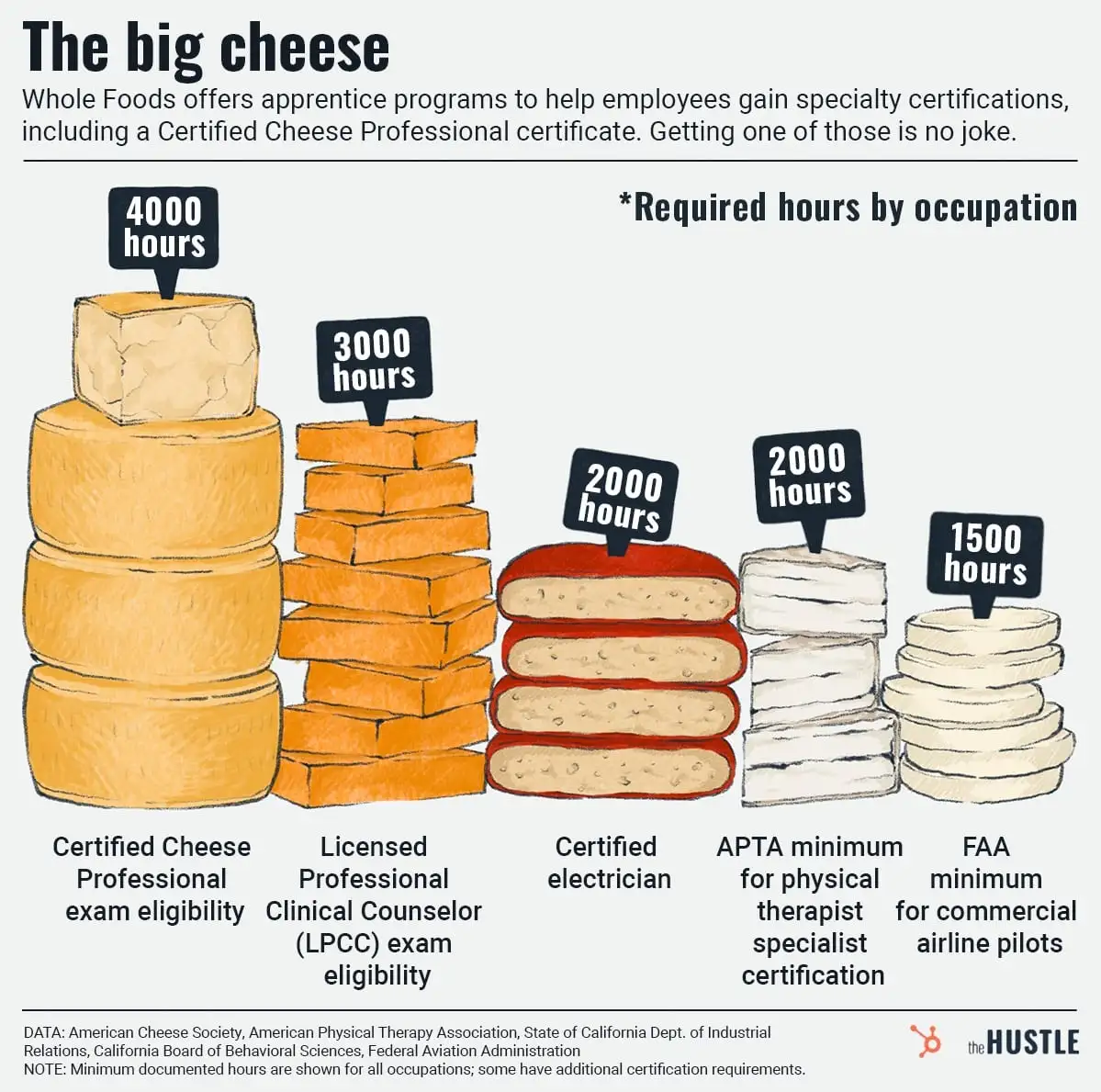

Career development could be an ace up Whole Foods’ sleeve